Pneumatic conveying with roots blower is a method of conveying materials through pipelines with a certain velocity of airflow. The use of pneumatic conveying has a long history. We use it to transport mail and bulk materials such as cotton and sand. At present, many industries use pneumatic conveying with Roots blowers. They include cast iron, cement plant, power plant fly ash delivery, chemical, building materials, grain processing and storage, machinery manufacturing and so on.

A. Four Types of pneumatic conveying

According to the air pressure state of the conveying system, it includes four types. Including suction type, pressure feed type, hybrid type, and circulation type. Among them, the most popular is positive pressure dense phase pneumatic transmission.

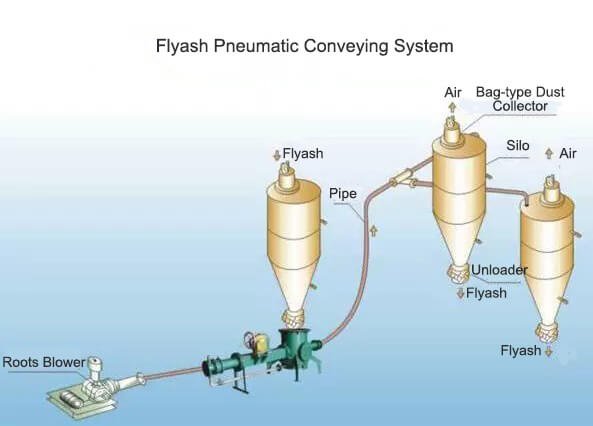

The pneumatic conveying system includes a feeding device, a sending tank pump, a pipeline, a valve, top dust removing device, a bottom gasification device, a bottom discharge device, a power gas source(roots blower), and a program control device.

Here is the working principle and operation stage of the positive pressure dense phase pneumatic conveying system. The positive pressure dense phase fluidization pneumatic ash removal system is developed by combining fluidization and gas-solid two-phase flow technology. The transmitter carries out fluidization and material transportation simultaneously. It usually consists of five phases:

Firstly: Closes the transmitter inlet with a Reliable, high-strength dome valve.

Second: The conveying air is introduced into the transmitter through the fluidized disk, thus fully flowing the dry ash.

Third: To transport the ash while flowing in a continuous dense phase.

Fourth: Maintain the applied air pressure until the dry ash enters the ash silo.

Fifth: Discharge the air that enters the ash silo by the bag filter.

Usually, we use PLC to control the entire operation process automatically. However, manual control is also possible.

B. The advantages of the Roots blower in pneumatic conveying:

1. High operation efficiency.

2. Equipment is simple. At the same time, the investment and maintenance cost of the equipment is low.

3. Transmission range is large while spending less labor.

4. The conveying pipeline is flexibly arranged to rationalize the configuration of the plant equipment.

5. The layout of the production workshop is relatively easy.

6. For materials with unstable chemical properties, they can use inert gas to transport.

C. Notes:

1. Check the accumulated water in the storage tank every day.

2. Check each valve for abnormality every day.

3. To check whether the circuit, gas path, pipeline are abnormal every day.

4. Pay attention to the seal of the three-lobe Roots blower. When under-pressure is found, check the pressure gauge in time. If the gauge pressure is low, the following reasons may occur.

1)the air supply pressure is insufficient.

2) the seal ring is broken.

3) Replace the seal.

Check if the pressure sensor is working properly; check the connection of the pipe or joint.

5. Always pay attention to whether the pneumatic valve is in place.

6. Pay attention to the high-pressure alarm during the transportation process at any time.

7. Do not disassemble and maintain the piping system under pressure.

Generally speaking, the above is a brief introduction of the pneumatic conveying system with roots blowers. If you encounter any technical problems during the use and maintenance of the Roots blower, please contact us. We will provide you with professional services.