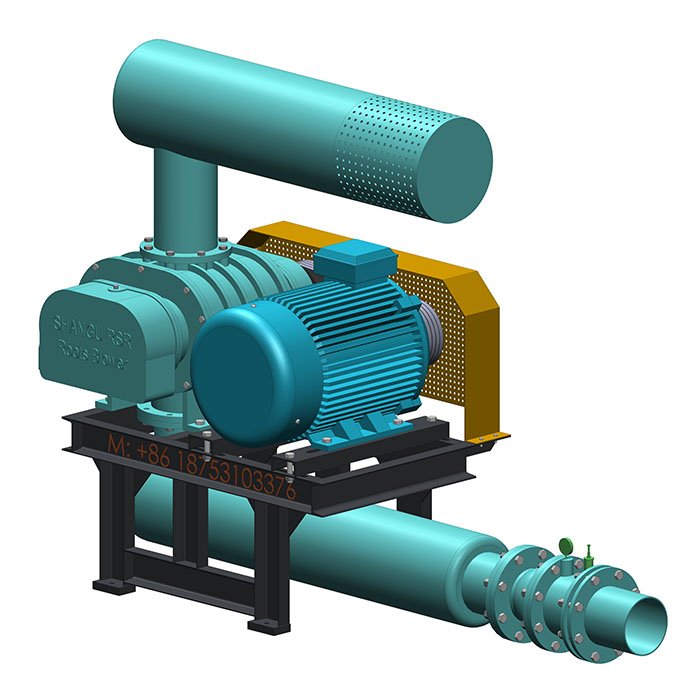

MJSR Series ROOTs Blower units

MJSR SERIES THREE LOBES ROOTS BLOWER

- Pressure Rise:9.8-98Kpa

- Air Capacity:2-94m³/min

- Motor Power:2.2-220kw

- Bore Size:80-200mm

- Drive model:Belt or Coupling

MJSR SERIES THREE LOBES ROOTS BLOWER

Shangu three lobes Roots Blower are new series Roots type blowers. With the help of CNC machine, we made precise rotors and casings to get a perfect gap to promote air performance, lower vibrations and noises results a significant improvement compared to traditional two lobe Roots Blower.Traditional Roots Blower lubricate bearings and gears with grease and oil.Shangu blowers with double oil tank need oil only.It is very convenient to maintain and oil has a better lubricating effect than grease. So it could be a longer bearings and gears life.

We currently produce 8 sizes of ROOTs blower units.

Main Advantages

The overall concept of the unit arrangement is designed with emphasis on maximum reliability and functionality, easy inspection, and maintenance.

- Low operating costs

- Easy operation

- Convenient Maintenance

- Oil Free Air

- Low Noise thanks to Special Casing Design and Combined Silencer

- All parts are Machined by CNC Center to ensure accuracy

- All blowers undergo two hours of testing to ensure that only qualified products can leave the factory

- All impellers have undergone dynamic balance testing

- Water Cooling for Lubrication Oil

Supply Scope

- Roots Blower

- Common Base

- Couplings

- Coupling Safety Cover

- Foundation Bolt

- Inlet Silencer

- Flexible Connector

- Outlet Silencer

- Pressure Gauge

- Safety Valve

- Check Valve

- Starting Oil Filling

- Electric Motor in Efficiency Class IE3

- Flange Pads

- Operation & Maintenance Manual

Optional Equipment

- Soundproof Enclosure

- Bearing Vibration Sensor

- Bearing Temperature Sensor

- Lubrication Oil Temperature Sensor

- Suction & Discharge Pressure Sensor

- Suction & Discharge Temperature Sensor

- Matting Flange

- Frequency Converter Control Cabinet

Applications

- Aeration of tanks at the WWTP

- Pneumatic transport

- Aquaculture Aeration

- Flotation

- VPSA Oxygen Plant

- Gas Combustion Supporting

- Food Vacuum Package

- Special Gas Delivery(Biogas)

- Power Plant

- Cement Plant Kiln Air Supply

Technical Parameters

| Model | Bore Size/mm | Pressure/kPa | Air volume m3 /min | Motor Power/kw |

| MJSR80 | 80 | 9.8-98.0 | 2.35-6.43 | 1.5-18.5 |

| MJSR100 | 100 | 9.8-78.4 | 3.75-10.31 | 2.2-18.5 |

| MJSR125 | 125 | 9.8-98.0 | 4.91-13.66 | 4-37 |

| MJSR150C | 150 | 9.8-58.8 | 9.28-18.38 | 44316 |

| MJSR150 | 150 | 9.8-98.0 | 12.63-30.19 | 5.5-75 |

| MJSR200H | 200 | 9.8-98.0 | 25.73-50.15 | 11-110 |

| MJSR200 | 200 | 9.8-98.0 | 33.01-59.32 | 15-160 |

Frequently asked questions

For all sizes of unts, we produce our own acoustic covers, adapted to the location and customer requirements. These in conjunction with our silencers show a high noise attenuation efficiency.

At the same time, we design the set in the middle band of the speed spectrum so that the resulting sound pressure level is as low as possible.

If we know all the parameters, then processing and sending the offer is a matter of a few hours.