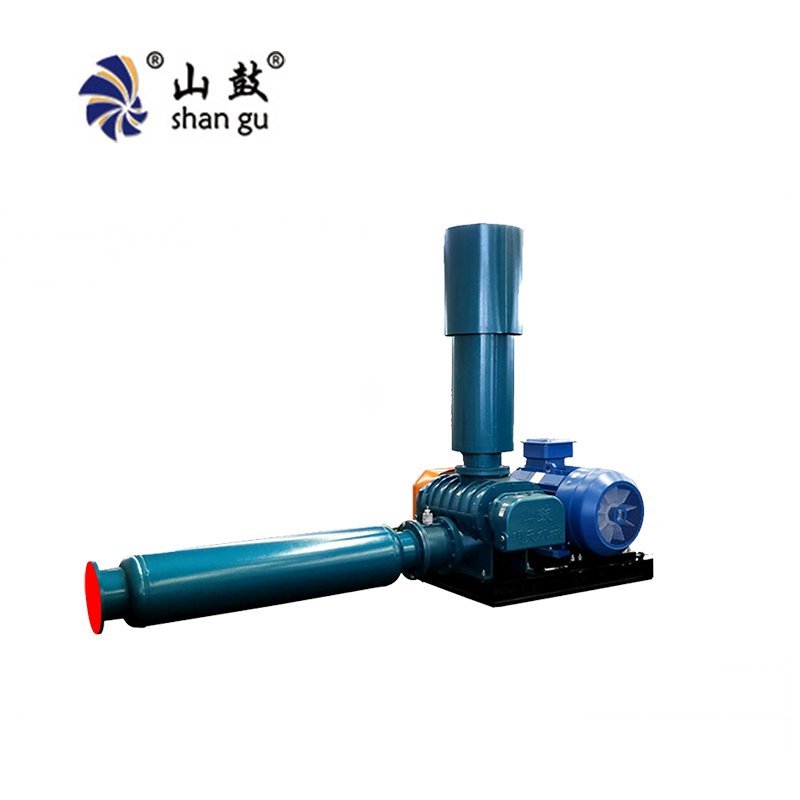

The pneumatic conveying system uses the Roots blower as a gas source. It can transport powdery, granular, and fibrous materials. They include phosphate rock, coal powder, cement, carbon black, polyethylene, polypropylene, cotton, etc. Small pieces of material such as coal, rock.

Advantages

Pneumatic conveying system with roots blower has a wide Applications. This is mainly because it has the following advantages:

(1) It transports the material in a closed pipeline. It is not easy to produce dust pollution to the environment. At the same time, the environment will not cause pollution to the materials or cause it to be damp. Thus it can guarantee the quality of the transported materials.

(2) It is easy to arrange the transmission line. Its floor space is small so that the space can be fully utilized.

(3) During material transportation, we can complete various production processes such as cooling, heating, and drying of materials.

(4) There are only a few mechanical transmission parts. The structure is simple. So the operation and management are convenient. The maintenance cost is low.

(5) It can do quantitative transportation. It is convenient for production scheduling and management.

(6) It can transport materials over long distances.

(7) It can transport Chemically unstable materials with inert gas.

Disadvantages

There are also some shortcomings in the pneumatic conveying system. The main disadvantages are:

(1) Large Power consumption.

(2) The components in the conveying pipeline are easy to be worn out. Because they are contacting with the airflow and the material. It is even harder, especially when conveying materials with high abrasiveness.

(3) It can not transport some materials, such as the following:

Brittle materials. They can cause mass degradation due to crushing or fail to pass the product;

Viscous materials or materials. They are easy to absorb moisture. Agglomerate is not suitable for use. Because they are easily blocked during transportation;

Grinding materials. They can cause damage of the line easily;

For the easily oxidizable material, we should transport them with inert gas;

If the Materials size is more than 50mm with high density, the system can not transport them.

Is it economical to use pneumatic conveying?

Although it has the above disadvantages, the total maintenance cost and operating cost per ton is much lower than other modes of transportation. If we can shorten loading and unloading time, we can improve the utilization rate of vehicles and vessels. Then the problem of higher power costs can be compensated. If we use other transportation methods to transport flour, granulated sugar, drugs or other foods, we need to carry our special treatment for hygienic protection. However, there is no requirement for pneumatic conveying. Although the cost of pneumatic power transmission is relatively expensive, the overall operating cost is much cheaper.