At present, wastewater treatment technology mainly uses the activated sludge method. Because It has the advantages of Mature technology and low operating cost. However, what is one of the most critical core equipment in the activated sludge treatment process? The answer is the blower. Now let’s have a look at the Blower Development Trend In The Sewage Treatment Industry.

To treat the municipal sewage with an activated sludge treatment process, the air-water ratio is generally 3-10. (The Ratio means the air volume of the blower to the volume of the treated sewage. However, to treat industrial wastewater treatment, it may reach about 35. This is because the composition of industrial wastewater is more complex. Therefore, the performance requirements of the blower are much higher in the treatment of industrial wastewater.

Requirements For Blowers In The Treatment Of Industrial Wastewater With Activated Sludge

First, Adjustable

During the process of wastewater treatment, it requires that the air volume of the blower can be automatically adjusted under constant pressure. Therefore, The flow adjustment range of the blower should be wide. The adjustment efficiency should be high. Because Only meeting these requirements can guarantee the optimal operation of the biochemical system. Then to finally achieve the purpose of high efficiency and energy saving. At the same time, This is also the most needed in the actual operation of the project.

Second, Low Noise

In fact, The noise generated by the blower is the main source of noise in the sewage treatment plant. Consequently, sewage treatment plants need to build a blower house, which can reduce noise pollution. Therefore, choosing a low-noise blower can not only reduce noise pollution but also save construction cost. Finally, This will also make a contribution to saving investment costs.

Third, Low Energy Consumption

Under normal circumstances, the energy consumption cost of the sewage treatment plant will account for 40% to 80% of its total operating costs. As a matter of fact, the energy consumption of the blower accounts for about 57% of the total energy consumption. Therefore, the energy-saving performance of the blower is a key issue to consider when trying to reduce the operation costs of the sewage treatment plant.

Fourth, Easy To Install And Maintain

As the main equipment of the sewage treatment plant, the blower should be easy for installation and maintenance. In this case, It is an important consideration in the process of selecting a blower for an industrial sewage treatment plant.

What Is The Blower Development Trend In The Future?

Generally Speaking,There are mainly five types of blowers used in the sewage treatment industry. They are a Roots blower; multi-stage centrifugal blower; single-stage high-speed centrifugal blower; air suspension blower and Magnetic suspension blower.

Firstly.Gradually Eliminated

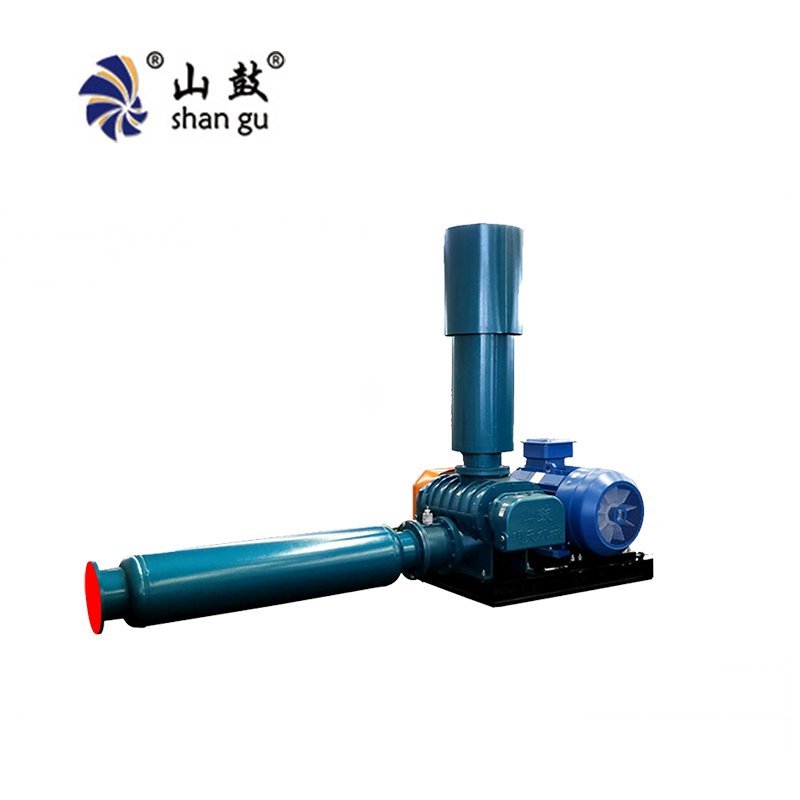

Roots blower and multi-stage centrifugal blower have the following shortcomings. Low working efficiency, high noise, high energy consumption, large size, and heavyweight. The air volume adjustment performance of these two blowers is relatively poor. Therefore, these two types of blowers have been gradually eliminated in the sewage treatment plants in some advanced countries. However, they still occupy a large market share in developing countries. Because they have an absolute advantage in price.

Secondly.The Current Mainstream Type

The single-stage high-speed centrifugal blower has the following advantages. Small weight and size, high working efficiency, low energy consumption, wide adjustable flow range, and high automation. Therefore, the single-stage high-speed centrifugal blower has become the mainstream type of blower for the sewage treatment industries recently.

Thirdly.Blower Development Trend In The Future

In general, Air suspension blowers and magnetic Turbo blowers will be the development trend of blowers. These two types of blowers belong to the new style single-stage high-speed centrifugal blowers. They use advanced air suspension bearings or magnetic suspension bearings technology. So they can meet various requirements of the sewage treatment plants. For example a wide range of blower air volume adjustment, low vibration frequency, low energy consumption, convenient installation as well as low maintenance cost. Therefore, these two types of blowers will become the first choice for the sewage treatment industry in the future.

Although Roots blower has many disadvantages, it still occupies this certain market as a result of its absolute advantage in price. In order to avoid being eliminated by the market, the Roots blowers industry should focus on the following aspects.

Firstly, Improve Efficiency

Optimize the impeller profile. This will help to improve the internal sealing effect of the impeller “meshing” gap. At the same time, Improve the manufacturing accuracy of the blower to make sure the uniformity of the rotor gap, and make it as narrow as possible. Thereby it can reduce gas leakage and improve volumetric efficiency. In addition, it is necessary to select the motor reasonably to avoid the situation of big horse-drawn carts.

Secondly, Noise Reduction

Focus on the development of low-noise technologies. These include pre-intake structure design and processing of twisted-blade rotors. These technologies can reduce gas flow pulsation and aerodynamic noise. At the same time, the balance of the impeller and the manufacturing accuracy of the synchronous gear should be continuously improved. Then This will reduce vibration and mechanical noise. In most cases, the end customers need to take some measures such as noise reduction and sound insulation to control the radiation of noise. On the whole, A variety of measures should be taken to meet user requirements for noise reduction.

Thirdly, Enhanced Reliability

We should pay attention to improving product quality and safety protection measures. Furthermore, Improve the quality of the blower to make sure long life service. With the help of computer control technology, we can automatically monitor the operating parameters, such as the pressure, oil temperature, and current of the blower. In this case, we can control the starting, running, and stopping process of the blower and make it in a safe, stable, and reliable controlled state.

Fourthly, Expand The Scope Of Application

We should Pay attention to the research of sealing technology and material technology. Improve the sealing, wear resistance, corrosion resistance, flame retardant, and explosion resistance of the product. Thus it can meet the transportation requirements of various gas,such as flammable, explosive, toxic, dusty, and corrosive gases. We can also develop marketable products for special requirements, such as high temperature, high pressure, or high negative pressure. In one word, These measures can help to expand the application range of Roots blowers.

Above is the Blower Development Trend in the sewage treatment industry. If you have any questions, please leave a message and we will discuss them together.