Roots Blower is not only important equipment in the cement production process but also one of the equipment with the largest power consumption. However, a considerable part of this consumption is not used for production needs, but wasted in vain! Under the increasingly fierce market conditions of industrial competition, enterprises must take various measures to continuously improve their competitiveness in the market competition, so as to win the market. Therefore, improving production efficiency and reducing product consumption are important measures to improve the competitiveness of enterprises. Today, let’s look at the Application Of Frequency Converter In Roots Blower Of Cement Plant.

Introduction of Kiln in the Cement Plant

The main equipment for cement production is a kiln, including vertical (shaft kiln) and horizontal (rotary kiln). In terms of production efficiency, a shaft kiln is lower than a rotary kiln. However, shaft kiln still accounts for a large proportion in practical application. Moreover, it is impossible for all these shaft kilns to withdraw from production and application immediately. It is of great practical significance to improve the technology of a shaft kiln that cannot be withdrawn from production within 3 ~ 5 years.

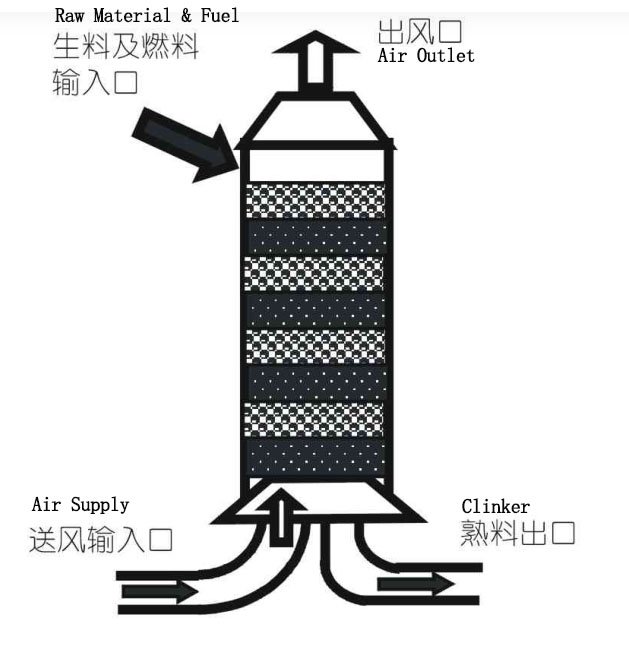

In the production process of the shaft kiln, send fuel and cement raw materials respectively into the kiln body from the top of the shaft kiln. Mixed combustion is carried out in the middle of the shaft kiln. The blower will send the air required for combustion from the bottom of the kiln by the blower. After combustion,r. The clinker produced will come out from the bottom outlet of the kiln.

Existing problems

The demand for air capacity in the production process depends on the quantity of fuel and raw materials. In addition, the demand for air varies greatly in different time periods in the whole production process. Therefore, in the whole production process, the air capacity sent to the kiln needs to be adjusted frequently.

In the traditional air supply system, the roots blower operates at the rated speed at all times. That is, the air supply capacity is fixed. We can only adjust the air capacity by the switch of the vent valve. In other words, whenever the demand for air in the kiln decreases, it is the time when energy waste occurs. The smaller the air capacity required by the kiln, the more energy waste. According to the statistics of a production site, the kiln rarely needs full air volume, which is 80% of the full air volume in half of the time, and about 65% of the full air volume in the other half of the time. In this case, the unnecessary 20% and 35% of the air capacity are wasted. The energy waste of the former is about 48%, while the energy waste of the latter reaches 65%!

Actions taken by the cement plant

In view of the above situation, in recent years, cement plants have upgraded the air supply system of kilns. The traditional low-efficiency air volume regulation mode is changed by using a frequency converter. It is very simple to improve the kiln air supply with a frequency converter without any change to the original system. Just close the original vent valve, control the blower by the frequency converter and adjust the airflow. At the same, the motor should be changed to a Variable frequency type. Generally speaking, the return on investment is very high. The following is a case of the Application of a frequency converter in a cement plant.

case study Of Frequency Converter In Roots Blower Of Cement Plant

The cement plant has improved the blowers of several kilns. They change the ordinary motor to a frequency conversion motor and add the frequency conversion control system. The model of one roots blower with a nominal power of 185kW is MTRG400. The parameters are as follows:

Flow: 280m3/min; Pressure rise: 29.4kpa; Rotary Speed: 730rpm

Before improvement, the operating power of the roots blower is about 155kw and the annual power consumption is about 1339200kw. A VI T5250 frequency converter controls the rotary speed of the roots blower. The operation conditions of the improved air supply system are 33hz and 20Hz, and the operation time is in half. The actual operating power of the former is about 88kw, and the operating power of the latter is about 23KW. The saved operating power is 155-88 = 67kw for the former and 155-23 = 132kw for the latter. Based on the average power saving of 90kw, the annual power saving is 90 × 24 x 365 = 788400kw. The power-saving rate is about 58%. According to the total installation cost of 800000RMB, they can recover the investment in about 8 months.

conclusion

The above is the application of frequency converter in Roots blower of cement plant. The use of frequency converter can greatly improve the efficiency of Roots blower, save energy consumption, reduce product production cost and enhance the market competitiveness of enterprises.