Introduction

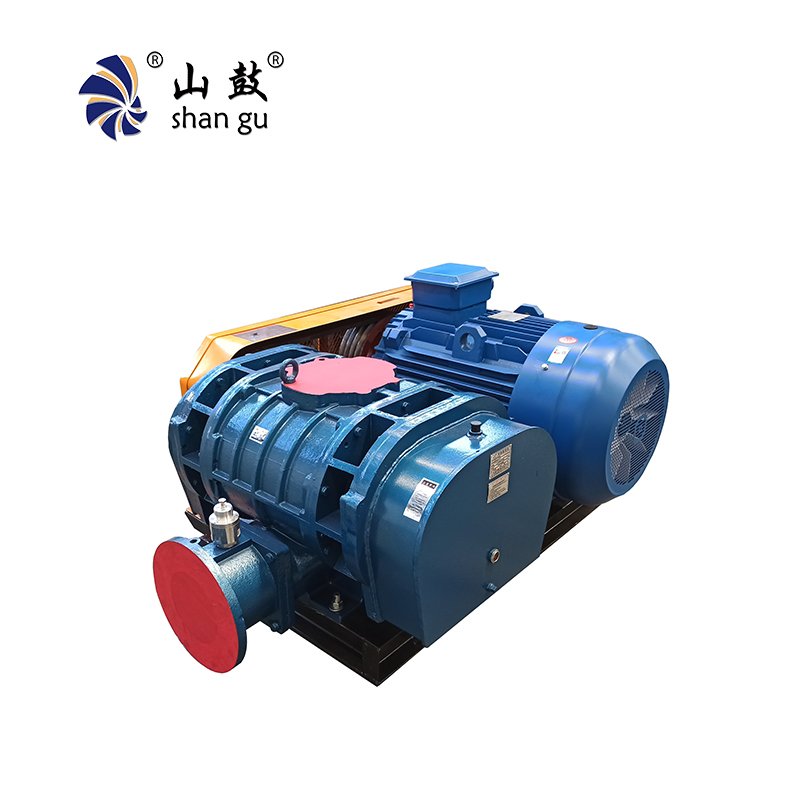

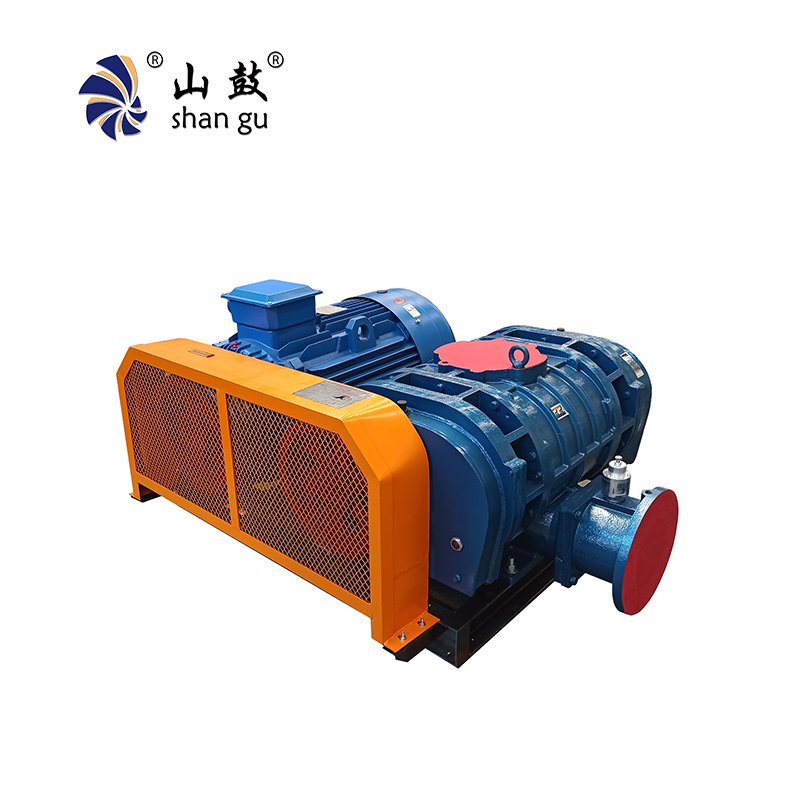

The paper manufacturing industry relies heavily on efficient vacuum systems for various processes, including dewatering, suction, and filtration. Among the different types of vacuum pumps available, Roots vacuum pumps (also known as blowers or rotary lobe pumps) have become a preferred choice due to their high efficiency, reliability, and ability to handle large volumes of air and vapor. This article explores the key applications, benefits, and considerations of using Roots vacuum pumps in paper mills.

Key Applications in Paper Mills

- Vacuum Dewatering in Paper Machines

- In the forming and press sections of paper machines, vacuum dewatering is essential to remove water from the pulp slurry. Roots vacuum pumps provide the necessary suction to enhance water extraction, improving sheet formation and reducing drying energy.

- Suction Boxes and Foilament Wires

- Roots pumps are used in suction boxes to maintain consistent vacuum levels, ensuring uniform paper thickness and quality. They also assist in removing water from the wire section, preventing sheet breaks and improving production efficiency.

- Pulp Filtration and Cleaning

- Vacuum pumps aid in filtering pulp suspensions and removing impurities. Roots pumps, with their oil-free operation, prevent contamination, making them ideal for maintaining pulp purity.

- Black Liquor Recovery in Kraft Pulping

- In chemical pulping processes, Roots vacuum pumps help evaporate black liquor by maintaining vacuum in multiple-effect evaporators, enhancing energy recovery and reducing environmental impact.

Advantages of Roots Vacuum Pumps in Paper Mills

- High Flow Rates: Roots pumps excel in handling large air volumes, making them suitable for high-speed paper machines.

- Energy Efficiency: Their positive displacement mechanism ensures lower power consumption compared to liquid ring pumps.

- Oil-Free Operation: Since Roots pumps do not use oil for sealing, they eliminate the risk of oil contamination in paper products.

- Low Maintenance: With no internal friction or wear-prone parts, these pumps require minimal maintenance, reducing downtime.

- Robust Performance: They maintain stable vacuum levels even under varying process conditions, ensuring consistent paper quality.

Considerations for Optimal Performance

- Proper Sizing: Selecting the right pump capacity based on vacuum requirements is crucial for efficiency.

- Dust and Moisture Handling: Paper mills generate dust and moisture, so filtration and cooling systems should be integrated to protect the pump.

- Regular Maintenance: Although low-maintenance, periodic checks of seals, bearings, and rotors are necessary to ensure longevity.

Conclusion-Roots Vacuum Pumps Paper Mills

Roots vacuum pumps play a vital role in modern paper mills by enhancing dewatering, filtration, and overall process efficiency. Their energy-efficient, oil-free operation makes them a sustainable choice for the paper industry. By selecting the appropriate pump and maintaining it properly, paper manufacturers can achieve higher productivity, better product quality, and reduced operational costs.

As paper mills continue to adopt advanced technologies, Roots vacuum pumps will remain a critical component in optimizing vacuum-dependent processes, supporting both economic and environmental sustainability.