Products

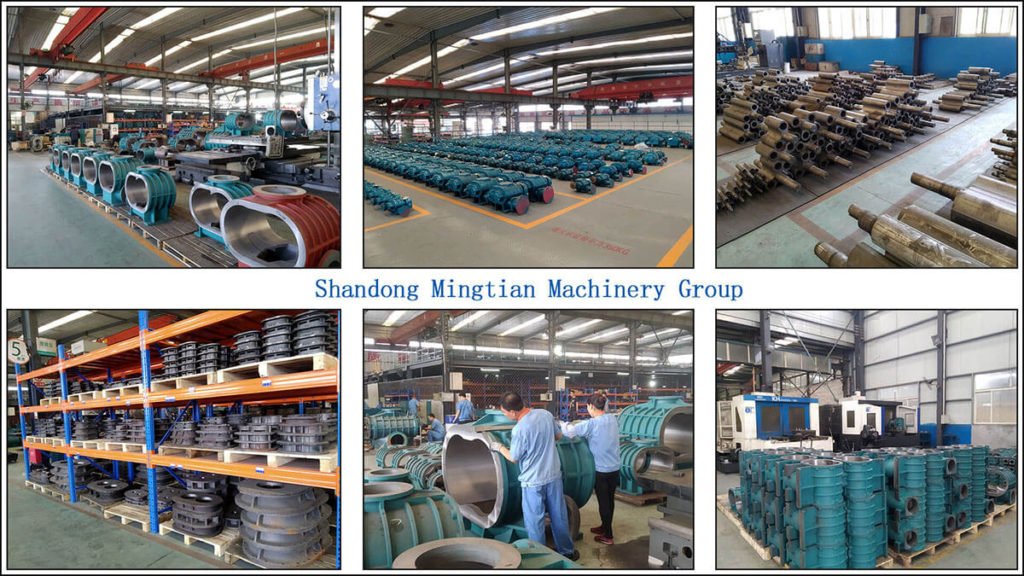

China Roots MVR Steam Compressor Supplier and Manufacturer Since 2007

Roots MVR Steam Compressor

Material:Stainless Steel2205

Sealing:Mechanical Sealing

Delta Temperature:20℃

Motor Power:0.75-280kw

Bore Size:50-600mm

Evaporation Capacity:200-12000kg/hour

Drive model:Belt or Coupling

Introduction

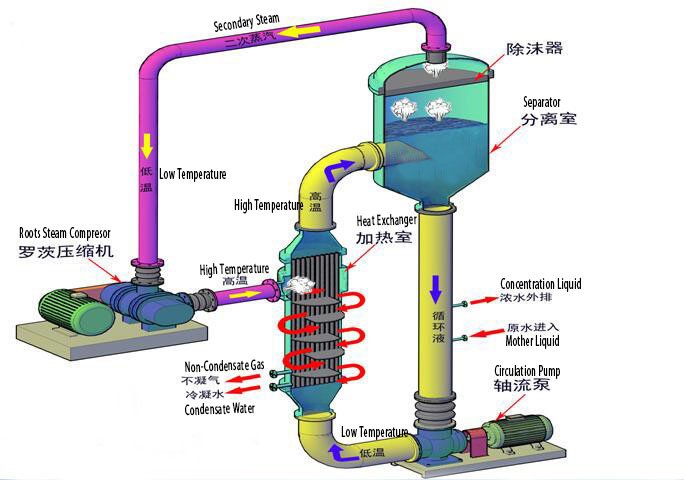

MVR is the abbreviation of mechanical vapor recompression technology. ZQRSR series products are steam compressors specially developed by our company for MVR system. High temperature steam corrosion and leakage are two main problems in the use of steam compressor. Based on our accumulated experience for many years, we have summarized the solution of 2205 stainless steel+mechanical seal. SS2205 has better chemical and mechanical performance than SS304 or 316. Mechanical sealing can 100% prevent the leakage of steam from the shaft.

Specifications

| No. | Model | Bore Size(mm) | Air Capacity (m³/min) | Evaporation Capacity(kg/hr) | Inlet | Outlet | Rotary Speed | ||

| ℃ | kpa abs | ℃ | kpa abs | ||||||

| 1 | ZQRSR80 | 80 | 0.5-6 | 10-150 | 85 | 57.81 | 105 | 116.6 | 1400-1800 |

| 2 | ZQRSR100 | 100 | 1-10 | 20-200 | 85 | 57.81 | 105 | 116.6 | 1200-1800 |

| 3 | ZQRSR125 | 125 | 1.5-19 | 30-400 | 85 | 57.81 | 105 | 116.6 | 980-1800 |

| 4 | ZQRSR150 | 150 | 3-26 | 50-600 | 85 | 57.81 | 105 | 116.6 | 800-1800 |

| 5 | ZQRSR200 | 200 | 15-55 | 300-1200 | 85 | 57.81 | 105 | 116.6 | 750-1600 |

| 6 | ZQRSR250D | 250 | 22-95 | 500-2000 | 85 | 57.81 | 105 | 116.6 | 750-1900 |

| 7 | ZQRSR250 | 250 | 27-85 | 600-1800 | 85 | 57.81 | 105 | 116.6 | 700-1500 |

| 8 | ZQRSR300 | 300 | 37-121 | 800-2600 | 85 | 57.81 | 105 | 116.6 | 700-1500 |

| 9 | ZQRF300 | 300 | 30-150 | 600-3200 | 85 | 57.81 | 105 | 116.6 | 400-980 |

| 10 | ZQRF350 | 350 | 37-180 | 800-4000 | 85 | 57.81 | 105 | 116.6 | 400-980 |

| 11 | ZQRF400 | 400 | 44-205 | 1000-4500 | 85 | 57.81 | 105 | 116.6 | 400-980 |

| 12 | ZQRG400 | 400 | 55-250 | 1200-5300 | 85 | 57.81 | 105 | 116.6 | 300-730 |

| 13 | ZQRG450 | 450 | 75-305 | 1500-6500 | 85 | 57.81 | 105 | 116.6 | 300-730 |

| 14 | ZQRG500 | 500 | 100-380 | 2000-8500 | 85 | 57.81 | 105 | 116.6 | 300-730 |

| 15 | ZQRZ600 | 600 | 120-450 | 2600-10000 | 85 | 57.81 | 105 | 116.6 | 300-730 |

| 16 | ZQRH600 | 600 | 200-560 | 4500-12000 | 85 | 57.81 | 105 | 116.6 | 250-590 |

1. The Evaporation Capacity and Air capacity showing in the above table is calculated based on 85℃ inlet temperature, 20℃ Temperature rise.

2. As different system require different inlet temperature, temperature rise and evaporation capacity, please contact us for steam compressor model selection.

Applications

1.Fructose Concentration

2.Refinement of Chinese Traditional Medicines

3.Desalination of Industrial Sewage

4.Sea Water Desalination

5.Disposal of Rubbish Solution

6.Disposal of Chipping Emulsified Liquid

7. Mine Water Treatment

8. Power Plant Wastewater Treatment

9. Papermaking Wastewater Treatment

10. Inorganic Chemical Wastewater

11. RO Concentrated Water Treatment

12. Reclaimed Water Recycling Utilization

Projects

Shangu Steam Compressor Advantages

1)Shangu brand Roots MVR Steam Compressor adopts the assembled double-end professional mechanical seal to avoid seal failure and leakage of steam.Various materials such as the duplex stainless steel (2205),super duplex stainless steel (2507), Hastelloy and austenitic stainless steel(316,316L only for shell-wall plating and cast iron plating) can be designed according to the user’s choice which can effectively prevent internal corrosion of steam compressors.

2)Shangu series Roots steam compressor have have large air volume and large boost pressure coverage,and the product has a wide range of applications.The user can choose the applicable compressor.The processed capacity of the steam is 30-1500OKG, and boost temperature of the steam is 10-25 ℃.

3)The compressors are simple in structure, stable and reliable in operation, high in mechanical efficiency, easy to maintain.It is insensitive to dust, droplets and fibers contained in the steam to be transported: There is no lubrication on the rotor surface and the steam can not be polluted by the oil.

4)The impeller adopts a new profile, which has good sealing performance, smaller intenal leakage, and high efficiency and energy saving.The product has high processing precision, reliable operation and long service life.Independent cooling system protects high temperature components during shutdown.

5)The specific internal clearance of the rotor prevents the thermal expansion of the rotor caused by different materials from exceeding the residual gap value and internal friction occurrence.

6)The bearing adopts imported brand bearings,such as NSK or SKF, to ensure the precise positioning of the impeller and high stability during operation

7)The pulley adopts the expansion sleeve type with European standard, with long service life.The coupling (direct transmission) adopts standard high-strength elastic coupling,and the elastic component is made of rubber material with high quality.

8.With 5-100HZ variable frequency motor, the adjustment range of speed is wider, and it is more suitable for working condition.

Leave your message and Get a Free Quote Within 24 Hours

Required Parameters

In Order To Get An Offer Within 24 hours, Please Supply The Following Details As Much As You Can.

- Inlet Temperature ℃ or Pressure abs

- Outlet Temperature ℃ or Pressure abs

- Evaporation Capacity(kg/h)

- Electricity Voltage and Frequency

- Purchase Quantity