Products

China Magnetic Turbo Blower,Roots Blower,Roots Vacuum Pump,MVR Steam Compressor Supplier and Manufacturer Since 2007

MTRR Double Stage High Pressure Roots Blower

Bore size:50-400mm

Pressure Rise:98-196Kpa

Air Capacity:0.61-428m³/min

Motor Power:5.5-1000kw

Lubrication:Oil

Drive model:Belt or Coupling

Introduction

Shangu MTRR Series Double Stage Roots Blower are new series Roots type blowers. With the help of CNC machine, we made precise rotors and casings to get a perfect gap to promote air performance, lower vibrations and noises results a significant improvement compared to traditional two lobe Roots Blower.Traditional Roots Blower lubricate bearings and gears with grease and oil.Shangu blowers with double oil tank need oil only.It is very convenient to maintain and oil has a better lubricating effect than grease. So it could be a longer bearings and gears life.

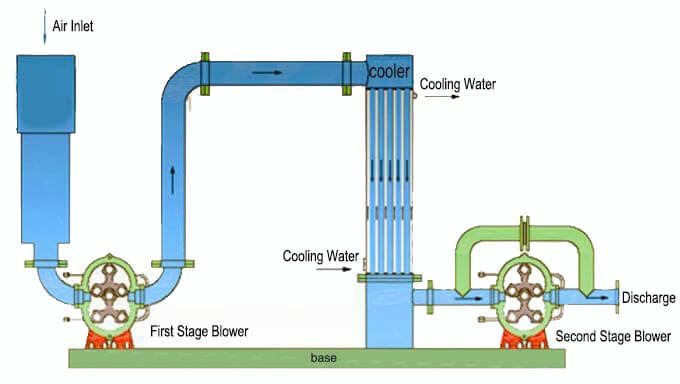

1. First Stage Roots Blower

2. Second Stage Roots Blower

3. Motor

4. Intercooler

5. Flexible Connector

6. Pipe Connector

7. Flexible Connector

8. Flexible Connector

9. Inlet Silencer

10. Safety Valve

11. Pressure Gauge

12. Flexible Connector

13.Outlet Silencer

14. Tee Joint

15. Butterfly Valve

16.Empty Silencer

17. Check Valve

18. Common Base

19. Foundation Bolt

20. Pressure Gauge

Operating Principle of MTRR Series Roots Blower

Shangu MTRR series is a two-stage roots blower. A middle cooling system is installed between the first and the second stage blower, which will cool the temperature of airflow out from the first stage blower,and then the temperature of airflow into the second stage blower will be normal and will not damage the blower. By the two stage compression, Shangu MTRR two stage roots blower can reach the maximum pressure of 196KPA.

The blower is of positive displacement type roots blower, and sends a fixed amount of air in proportion to its rotation speed.With the three-lobed rotors, the two rotors make three intake and exhaust cycles per revolution. Because the air has less pulse compared with the two-lobed type, fluctuations in load, noise and vibration are small. While the two three-lobed rotors mounted on two parallel shafts maintain only a very small clearance between themselves and the inner surfaces of the oval casing operation chamber and between each other, they are driven by timing gears, moving a fixed volume of the air enclosed by the casing and rotors from the intake side to the output side. The roots blower is free of Internal lubrication. And its simple design, easy handling, and stable performance make a wide range of applications possible.

Specifications of MTRR Series Roots Blower

| Model | Diameter(mm) | Pressure(kPa) | Air volume(m3 /min) | Power(kw) |

| MTRRB65 | 65 | 98-196.0 | 0.6-4.3 | 5.5-22 |

| MTRRB100 | 100 | 98-196.0 | 3.5-10.9 | 15-45 |

| MTRRB125 | 125 | 98-196.0 | 6.6-18.7 | 22-75 |

| MTRRD130 | 150 | 98-196.0 | 10.2-28.6 | 30-110 |

| MTRRD150 | 150 | 98-147.0 | 12.9-35.4 | 37-110 |

| MTRRE150 | 150 | 98-196.0 | 25.9-44.3 | 75-185 |

| MTRRE190 | 200 | 98-196.0 | 32.3-55.2 | 90-220 |

| MTRRE200 | 200 | 98-176.4 | 41.8-69.2 | 110-250 |

| MTRRE250 | 250 | 98-156.8 | 53.6-88.4 | 132-250 |

| MTRSR250 | 250 | 98-196.0 | 79.3-127.5 | 185-450 |

| MTRRE300 | 300 | 98-137.2 | 114.5-183.8 | 250-500 |

| MTRRF295 | 300 | 98-196.0 | 94.2-139.0 | 200-500 |

| MTRRF300 | 300 | 98-176.4 | 119.0-174.0 | 250-560 |

| MTRRF350 | 350 | 98-137.2 | 144.0-207.0 | 315-560 |

| MTRRF395 | 400 | 98-156.8 | 156.0-226.0 | 355-630 |

| MTRRG400 | 400 | 98-176.4 | 205.0-276.0 | 450-900 |

| MTRRG450 | 450 | 98-176.4 | 263.0-347.0 | 560-10 |

Applications

1. Wastewater/Sewage Treatment Plant

2. Cement Plant Kiln Air Supply

3. Quicklime Plant Kiln Air Supply

4. Pneumatic Conveying System

5. Power Plant

6. Special Gas Delivery(Biogas)

7. Gas Combustion Supporting

8. VPSA Oxygen Plant

Advantages

1.Strict management of quality standards.ISO9001 and CE systems.

2.Technical customization (size, pressure,design, pump accessories).

3.CNC machinery enabling precise measurements and grinding needed for more efficient pumping.

4.Fewer vibrations transmitted through the lobe, for longer-lasting shafts, gears and bearings.

5.Three-lobe design controls any backflow pressure towards rotor.

6.Oil and dust-free outlet.

7.Lubricated with high grade oil, proven to be a much better alternative to grease.

8.Significant improvement in air performance ratios: wider air, pressure and vacuum range.

9.Much quieter: our new design can effectively reduce noise by approximately 5 dB.

10.Lower energy consumption.

11.All our products can be used for OEM.

About Us

Leave Your Message And Get A Free Quote Within 24 Hours

Required Parameters

In Order To Get An Offer Within 24 hours, Please Supply The Following Details As Much As You Can.

- Pressure Rise

- Air Capacity

- Electricity Voltage and Frequency

- Purchase Quantity

- Project Details